Applications of thermography. Cases and problems that can be detected.

Today, the thermography It is one of the most used technologies in the installations sector, construction or even in the field of renewables.

The thermography applications they are innumerable in moments where it is not possible to locate and identify errors with the naked eye. Solution thermal imaging cameras! to discover what we do not see.

First, understand what it is and then how we can apply it to real work …

What is thermography

The thermography is a procedure used to obtain information about the temperature of an object from a distance, without using physical contact with it.

Infrared radiation from the electromagnetic spectrum is captured by cameras that can transform the radiated energy into information about the temperature of these elements.

But… What are the advantages of thermography? In relation to the use of this technique and its applications, its use to carry out energy audits, in energy rehabilitation of buildings, study of energy efficiency in the industrial, construction or renewable sectors stands out since allows to analyze the thermal behavioror. Emphasizing that it is very useful for the following reasons:

- It is a non-destructive procedure that, complemented with other field information obtained in situ, allows obtaining real data on its condition and the existence of possible pathologies of the construction elements of the building.

- It allows providing information on patterns, behaviors and thermal anomalies in certain areas of the building envelope.

- It allows real-time evaluation during the collection of information with the camera.

To translate this concept into the real world, the thermographic camera.

Thermal imaging cameras: How it works and use

The operation of the thermal imaging camera is based on a radiation detector that captures infrared radiation emitted by objects so that said radiation will be read and interpreted by the camera.

From the image obtained, various colors can be seen that correspond to the different emitted, absorbed and reflected long-wave infrared radiation signals that come from the analyzed element. Obtaining a temperature pattern on its thermal behavior.

Thermal cameras help us make visible problems that cannot be seen with the naked eye

But… How to do thermographic inspections? The steps could be expressed as:

- Define the task and data collection. In buildings, offices, warehouses, etc. Remember to measure indoor and outdoor temperatures. Make sure the temperature difference is sufficient for building inspection (a minimum difference of 10 ° C is recommended).

- Start from the outside. Remember to take thermal images of areas whose conditions appear to be good, both to avoid surprises and to compare.

- Continue inside (For buildings). Remember to remove the furniture from the exterior walls and remove the curtains. At least six hours before the inspection so that the insulating properties of the furniture do not influence the thermal readings of the thermal imaging camera.

- Perform an air tightness check (For buildings). «Door-fan» test, the so-called Blower Door Test - Air Tightness Test.

- Analysis and reporting.

At a minimum, during the process of taking a thermal image, the following standards, among others, must be observed:

- Proper framing of the imageIn such a way that the object will be clearly visible, in the position that provides the most information, getting as close as possible.

- Proper approach to avoid taking wrong measures as well as aproper setting of the temperature range,It is not convenient to set a very wide range for greater accuracy and precision in the measurement.

- Direct sun radiation should be avoided,so it is convenient that it be carried out in the afternoon when the sun does not affect directly.

Thermography application: Cases and problems that can be detected.

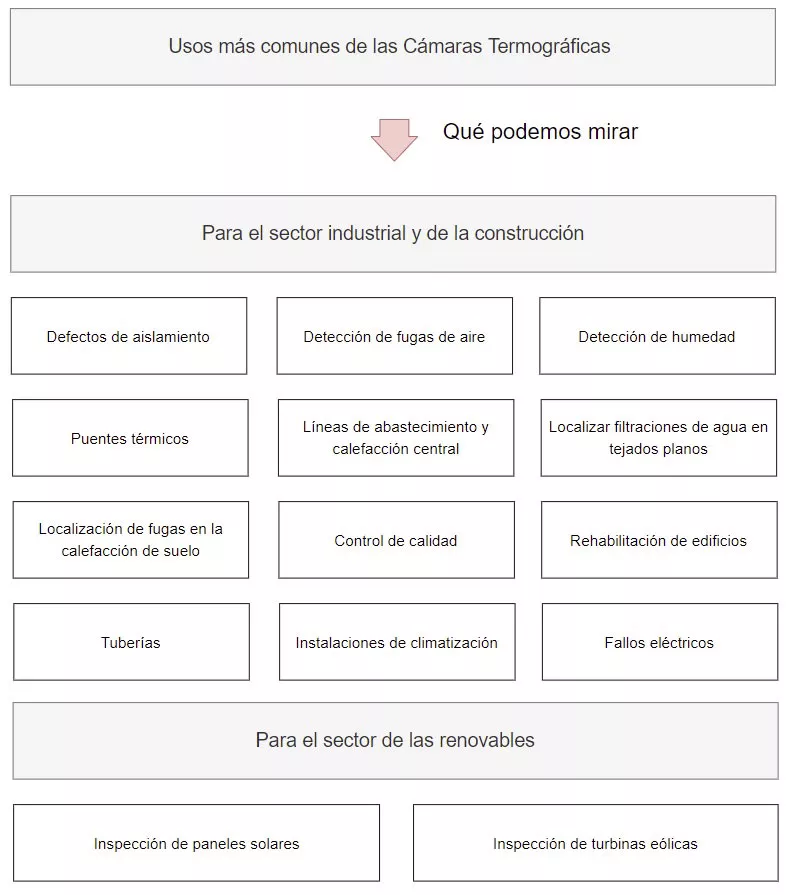

As we mentioned at the beginning, the uses of thermography It is useful for the analysis of the building envelope or facilities systems, but it is also used to inspect wind turbines or solar panels:

The most common uses in thermography applications are:

- Visualize energy losses

- Detect a lack of insulation or faulty insulation

- Locate air leaks

- Find moisture in insulation, on the roofs and walls, both in the interior and exterior structure

- Detect mold and poorly insulated areas

- Locate thermal bridges

- Locate water leaks on flat roofs

- Detect breaks in pipes hot water

- Detect construction faults

- Monitor the drying of buildings

- Find faults in the power lines and in the central heating

- Detect electrical faults

- Solar panel inspection

- Wind turbine inspection

In the following PDF manual you can find more information on the practice of thermography in daily work.

To carry out a correct diagnosis, on the one hand it is required that the technician know how to properly use the camera and the software it uses, that is, that they have sufficient skill and experience with it.

To work properly in the field of thermography, the technician requires training; both theoretical and practical

The technician must also have the necessary theoretical training on how the transmission of heat between objects occurs (through conduction, convection and radiation), as well as on the operation of the laws of thermodynamics related to the behavior of heat.

Thermography in the thermal envelope:

Detection, location and verification of the status of areas with thermal bridges such as the meeting of the façade enclosures with slab or with pillars, the meeting of the façade with roofs, the perimeters of window openings (jambs and lintels), etc … or areas where there is no insulation or it has deteriorated.

In this image we can see a wall that presents an area with a lack of insulation, in the image on the left it is seen in bluish colors, with a cooler temperature than the rest of the wall.

Detection of areas with air leaks, so that in these areas there are also greater energy losses generating problems in the ventilation installations, as well as possible condensation.

Detection of humidity that can generate other damages or pathologies that end up affecting the rest of the building. In addition, it must be taken into account that condensation in certain inner layers of the enclosures, since the chambers do not usually have ventilation, makes drying them difficult and favors the appearance of other associated problems such as the presence of fungus or mold.

Detection of facade areas with excessive heating losses, In this case, thermography helps us to detect certain areas of the façade where heat escapes quickly to the outside, since the thickness of the façade was minimal and had hardly any thermal resistance, since they used to place the radiators or heat emitters in niches. generated consists of subtracting layers from the enclosure.

Thermography in facility systems:

Detection of problems in the components of high or low voltage electrical installations, and system failures, such as overvoltages, poorly made connections or internal damage, excessive overheating in some fuses or connections, etc …

Failure detection in mechanical installations, within these we find those of sanitary hot water, air conditioning and fire protection, allowing us to study the state in which its components are, and to detect any water leak, obstruction of pipes, deterioration or loss of insulation that they present, inadequate thicknesses insulation or incorrect placement of the same.

Observation of the condition of motors and pumping equipment so that a thermal image will help us detect overheated motors, overloaded pumps, hot bearings or lubrication problems, detecting these problems can help prevent more serious and costly repair damage from occurring.

They allow to carry out maintenance and verify the state of conservation of photovoltaic panels, so that only through monitoring and proper maintenance can the proper performance of said installation be guaranteed. With thermography, any type of anomaly can be detected in these panels, such as the presence of broken cells, cells with cracks or with defective welding between their joints.

What thermography cameras can I buy

Obviously there are many well-known models and manufacturers of thermal imaging cameras; Bosch, FLir, Fluke, etc. We just want to express that they are not cheap if you are looking for quality and that it is worth paying for a device that will last you for many years.

In the following video from Energy Manager, three different models of thermal imaging cameras are compared; from the basic, to the most expensive and powerful on the brand Flir and Fluke. A brand very recognized worldwide for its quality in thermographic technology and software:

- FLIR E30bx camera: Recommended for façade and facility reviews and inspections to show accurate element temperatures.

It is a calibrated equipment and through the support software we can carry out detailed studies of the thermal behavior of elements: Facades, ducts, vents, leaks, electrical panels, industrial processes, etc.

- FLUKE VT04 Camera: Recommended (essential) for electrical checks. Thermography of electrical paramenta.

It can be used to detect hot (or cold) spots on items at a greater distance, but it lacks accuracy. The values are merely indicative. It is very useful to use the camera to visualize a leak, but then we will have to access to measure it accurately up close.

- FLIR ONE PRO camera: This equipment is very versatile, inexpensive but not very precise.

It is the perfect tool for the energy auditor since it allows us to detect thermal deficiencies in insulation, leaks, overheating, etc. But your measurement is not accurate and we will not be able to make a judgment.

Conclusions:

The use of the thermography is necessary for energy audits or when an energy rehabilitation is going to be carried out, due to the objectivity and reliability that it provides to know the real state of the thermal behavior of the enclosure and facilities, but not only in these cases but also in the realization of the energy certificate.

Above all, because it is necessary to assess that, in a certain building, although it may present a good thickness of thermal insulation with good carpentry, good glass, etc …

If there is no correct information on how the areas with thermal bridges behave or on the presence of excessive areas with infiltrations or the existence of air leaks or heat losses, we will probably make an incorrect estimate of them when entering said information.

One of the most important points when it comes to correcting problems in the thermal envelope and that can deteriorate the building lies in the detection of cold areas or thermal bridges that could cause humidity.

These condensation humidity (See roof rehabilitation advice) are a potential problem that over the years can affect the structural elements of the building, if we also add that other types of humidity can converge due to leaks in the drainage network or in the ducts of the cold and / or hot water network, we are facing an even bigger problem, so it is essential to try to detect and correct them.

Likewise, in the case of installations, it is very useful to evaluate whether their performance is adequate and to verify that the components have not deteriorated or present any type of pathology that could end up impairing the operation of the installation. Obviously, if the equipment loses performance, the energy consumption skyrockets and, furthermore, these problems mentioned could affect considerably reducing the years of useful life of the installation.

-

Point of interest:

- Thermography video glossary … HERE.

- Low consumption light bulbs, the heads and tails … HERE.

- Architecture with containers. Advantages and disadvantages analysis …HERE.

- More than 100 guides on energy efficiency …HERE.

- Home automation and energy efficiency in Buildings …HERE.

Note: The images in this post are taken from a FENERCOM guide.